APPLICATION OF BIOTECHNOLOGY IN WASTE WATER TREATMENT

ABSTRACT

Most of the industrial effluents

contain biodegradable substances which can be treated by conventional

biological treatment methods such as activated sludge process, aerated lagoon

and aeration pond. The effluents generated from pulp and paper, chemical,

pharmaceutical, dyeing and dye manufacturing industries can not be treated by

the conventional methods due to the presence of recalcitrant compounds. The

white rot fungi, which are initially identified to have the ability to degrade

lignin, can be used for the treatment of effluent, generated from these

industries. It is observed that the white rot fungi have a non-specific enzyme

system, which oxidizes the recalcitrant compounds present in the effluent. in

this paper, application of this fungal treatment for removal of colour of waste

water from pulp plant and dying industries have been attempted using white rot

fungus trametes versico

INTRODUCTION

Due to rapid industrialization

and urbanization a lot of chemicals manufactured and used in day to day life

which includes dyes, pesticides insecticides and other chemicals, find their

way in the waste water generated from industries where such compounds are

manufactured and processed. These compounds are not easily amenable to

conventional biological treatment process such as activated sludge, aerated

lagoon and oxidation ponds. Effluents discharged from pulp mill and dying

wastewater are highly coloured due to the presence of lignin-related compounds

and dyes respectively.

Many synthetic dyes have been

used increasingly in textile and dyeing industries because of their case and

cost effectiveness in synthesis, fineness and variety in colour compared to

that of natural dyes. Number of dyes are

manufactured which include several varieties of dyes such an acidic reactive,

basic disperse, azo, diazo, anthraquinone based and Meta complex dyes. The

toxicological and ecological aspects of these dyes are complex to evaluate.

Some of the dyes are toxic carcinogenic and mutagenic.

Processes like dying and printing

are done cloth industries. The chemicals used in dying are napthol, reactive

colour, vats, pigments sulphurates, binder. HCL, Acetic acid, sodium nitrite

and urea white for printing, pigment colours, reactive colours, binders. Dying

and finishing wastewater from the textile industries are generally necessary to

affect adequate removal of contamination.

Many methods of

colour removal from dyeing and textile industries such as chemical coagulation,

chemical oxidation, electrochemical irradiation, ozonation and adsorption are

available but not implemented in the

industrial scale either due to cost or being environmentally unsound. The

ability of the white rot fungi to degrade a wide range of products of synthic

chemicals, many of which are recalcitrant to biodegradation has been reported.

Treatments of hazardous waste xenobiotic compounds, organo-pollutants and

mechanism by which the white rot fungi degrade pollutant have also been

revived.

The white rot fungus, Tramets versicolor

has a non-specific enzyme system which oxidizes the recalcitrant compounds. It

has been used for the decolorisation of paper and pulp mill effluents

biodegradation of azodyes, and polycyclic aromatic hydrocarbon compounds,

acenaphthene and acenaphthylene. In the present investigation, the removal of

colour from pulp mill effluent and dye from aqueous solution by the white rot

fungus Trametes versicolor MTCC138 grown under different culture conditions is

reported.

What Is biotechnology?

It is a technology which employs

biomaterial and biological principles to produce beneficial product of human

need.It is the effective use of technology by using biological agents for well

being of human kind.

CHARACTRISTICS

OF PULP AND PAPER INDUSTRIES

Pulp and paper is a major polluting industry

in India. The effluent from the pulp plant of a paper mill is dark brown in

colour and contains chlorinated organic compounds formed due to usage of

chlorine and its derivates in the pulp bleaching process. The chlorinated

organic compounds are identified as potentially hazardous. Carcinogenic,

mutagenic, persistent and bioaccumulative sample collected at site were brought

to laboratory analyzed for various parameters like COD, BOD SS and pH etc. as

per standard methods by AAHHA (1981).

The conventional

biological treatment system currently used in the pulp and paper industry such

as activated sludge process, aerated lagoon, anaerobic lagoon, stabilization

ponds etc. are successful in reducing the biochemical oxygen demand (BOD)from

the effluent whereas colour and chlorinated organic compounds are not removed.

Colour can be removed by precipitating with metal salts of aluminum, ferric and

ferrous. By using these metals salts experiment reports are high removal

efficiency. Salts remove color but retain its own colour. Mixed culture used in

the biological treatment system are capable of metabolizing soluble sugars and

some low molecular in the effluent, leading to reduction of BOD but lacks in an

enzyme system capable of oxidizing colour causing compounds (chloro-lignin).

Water pollution

and other environmental regulations in India are beginning to require industry

to substantially reduce the colour of effluents from industries aesthetically

unacceptable, reduce the light transmission through the contaminated waterways

thereby reducing the photosynthesis which will lead to depletion of dissolved

oxygen and pose a health hazard to the aquatic life in the receiving water

bodies.

MATERIAL

AND METHODS

a) Culture:

The white rot

fungus culture, trametes versicolor MTCC 138 was procured from Institute of

Microbial Technology, Chandigarh, India. The organism was maintained on agar

slants containing yeast extract (5g/L), glucose (10g/L) and agar=agar (15g/L)

and maintained at 40c. The pH of the medium before

solidification was adjusted to 5.8.

b) Medium Composition:

The basic growth

medium composition consists of 10g/L Glucose: 1g/L KH2PO4:1.75

g/L NH4CL:0.5g/L KCL; and 0.5g/LMgSO47H2O. The

initial pH of the medium was adjusted to 4.5.

c) Pulp mill effluent:

The effluent

samples used for the present studies procured from Tamilnadu, Newsprint and

paper Limited, Kagithapuram (Tamilnadu), India. The highly coloured effluent

from pulp plant utilizing bagasse as the raw material was collected in airtight

plastic cans (30L) and stored at 4±1oC.The characteristics of

effluents were determined according to standard methods for the examination of

water and wastewater. 17th edition APHA, Washington D.C. except for

colour, and are reported in table 1.

Table1 CHARACTERISTICS OF PULP MILL EFFLUENT

|

Parameter

|

Range

|

|

PH

|

8.5-9.5

|

|

Colour concentration(pt-co

units)

|

4500-4700

|

|

Total Solids(mg/L)

|

3200-3800

|

|

BOD (mg/L)

|

260-360

|

|

COD(mg/L)

|

4500-4800

|

COLOUR MEASUREMENTS

The colour of

pulp mill effluent was measured according to National Council Of the paper

industry For Air and Stream Improvement Standard Method (NCASI). The PH

of the original effluent sample was in the range of 8.5-9.5 and was adjusted

7.6 followed by filtration 0.45 µm filters. The absorbance of the filtrate was

measured at 465 nm against distilled water using 1-cm light path cuvette in a

UV spectrophotometer (shimadzu, Japan). PlatiniumCobalt Colour Units were

calculated as follows.

Colour units (CU) =500*A2/A2

Where,

A1-Absobance of sample at 465nm

A2-absorbance500CU pt-co standard at

465nm.

a) Dyes:

Remazol orange Remazol brown which

are commonly used in industries, were selected for the study. Dyes were

obtained from Colourchem, Mumbai, India.

b) Dye measurements:

The dye removal / disappearance was

determined spectrophoto-meterically by

monitoring the absorbance at or near the wavelength (maximum absorbance ) for each dye i.e. at 490 nm and 480 nm

forremazol orange and Remazol brown respectively.

EXPERIMENTAL

The experiments on effect of varying

concentrations of glucose and sucrose on colour and COD removal from pulp mill

effluent (sample) were carried out in shake flasks (250ml). The basic nutrients

were added to 100ml. of the effluent sample with varying concentrations of

glucose (2.5to50g/L) and sucrose (2.5 to 25g/L). Similarly batch experiments

were carried out in shake flask (250ml) containing10ml of aqueous solution

containing the medium mentioned above and dyes with 250 and 500mg/L

concentrations. The PH of the effluent was adjust to 4.5(optimum)

and autoclaved at 121oC for 15 min. after autoclaving. The flaks

were inoculated with the white rot fungus. Trametes versicolor kept in rotor

shaker (180rpm). After 7 days, the effluents were withdrawn, filtered through

0.45µm filters and analyzed for colour and COD using methods mentioned earlier.

RESULTS AND DISCUSSION

Treatments with pulp mill effluent from

the pulp mill utilizing bagasse as the raw material are shown in Table 1. The

effluent characteristics show more non- biodegradable substances, which were

represented by the chemical oxygen demand (COD) of effluent. From the

biochemical oxygen demand BOD/COD ratio of the effluent is less, which shows

that the effluent is not suitable to conventional biological treatment.

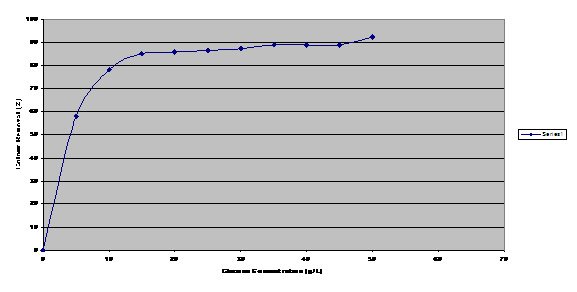

Effect of glucose concentration

The effect of

initial glucose concentration on colour removal efficiency is shown fig.1. In

the present study, the maximum colour removal 92.3%was obtained at a glucose

concentration of 50 g/L. From fig. 1. It is observed that the colour removal

efficiency does not increase significantly after 15g/L of glucose concentration

where about 85.2%were obtained. Also it is observed that the presences of

easily metabolically sugars are required for the growth of fungus and colour

removal which is supported by the earlier investigations. Colour removal is

secondary metabolic process and the fungus requires glucose or cellulose for

energy. Incubation with this fungus has not only reduced but also reduced COD

of the effluent considerably The maximum COD removal of 78%was observed at the

glucose concentration of 10g/L and further addition of glucose has increased

COD of the treated effluent due to the presence of unmetabolisable glucose left

with.

Effect of sucrose concentration

Fig. 2 Effect of sucrose

concentration on removal of efficiency

(PH-4.5,NH4CL

05g/L; Initial colour -4700 pt- Co and basic nutrients)

The effect of initial sucrose concentration

on colour removal efficiency is shown in fig.2 from fig 2, it is found that the

maximum colour removal efficiency significantly. In the control fiask that is

the flask without addition of sucrose showed no growth of fungus and hence

there was no colour removal supporting the earlier statements that fungus

requires easily biodegradable sugars for high growth. The maximum COD removal

of 73.3%was obtained at the sucrose concentration of 5g/L and as mentioned

earlier further addition of sucrose has increased the COD of treated effluent

due to the presence of the unused sucrose.

CONCLUSION

White rot fungus was found to be a suitable

absorbent for the absorption of dye from aqueous solution. The data collected

on the dye removal from aqueous solution with special reference to the ability

of white rot fungus Trametes versicolor to remove remazol orange and remazol

brown have been shown in Fig.3. it was observed that extensive removal of two

dyes by the culture of Trametes versicolor as evidenced by the decrease in the

absorbance of the culture medium. In the case of remazol brown, 97.6 and 98.7%

co lour removal efficiencies have been attained at 250 mg/L and 500 mg/L dye

concentration over a incubation period of 7 days respectively, whereas in case

of remazol orange, decolourisation was only 70.4 and 81.3%.

Use of

treated water in a place of fresh water reduces the fresh water demand in

industry, there by reducing the chemical consumption and saving in fresh water

cost.

REFERENCES

1) Introduction to Environmental Biotechnology ’-by

A.K. Chatterji.

2) ‘Removal of colour from wastewater using Tramates Versicolor’ - Paper by S.V.

Srinivasan and D.V.S.Murthy. (Journal IAEM. Vol.27, 260-264 (2000).

3)

www.atrp.gatch.edu/biosensor.html.

4)

www.grzyby.pl/gatunki/trametesversicolor.html.

5) www.discoverlife.org/nh/tx/fungi

No comments:

Post a Comment